Bamboo manufacturing machines are used to process raw bamboo into processed bamboo. Bamboo is usually a kind of grass, which grows abundantly in Asian countries like India, China and Tibet. Bamboo is noted for its flexibility as it can be a flexible plant which will expand in many different habitats and is particularly resistant to several varieties of pests. Bamboo is rapidly expanding and can be developed even on waste components like wood, leaves and straw. Bamboo can be effortlessly cultivated in any location.

Bamboo flooring machines allow it to be simple to manufacture hardwood flooring solutions, which include flooring, siding, decking, shingles and hardwood laminate. Bamboo has superior quality Qualities and can resist a lot of kinds of use and tear, such as dents, dings, nicks and gouges. Bamboo flooring may withstand exposure to ultraviolet rays within the Sunlight and from warmth and dampness. Bamboo flooring can be highly versatile and can easily conform to any House, even curved spaces. Bamboo flooring is made from thin strands of bamboo fibers that happen to be spun spherical a Main and glued to the backing.

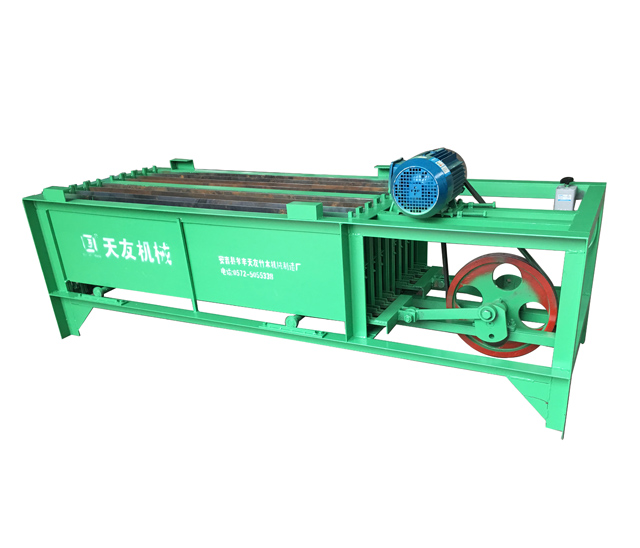

A Bamboo Flooring Equipment is created utilizing a conveying roller steady feed method that cuts open the bamboo tubes. Bamboo tubes are hand woven and hand cut into slim gauge strips of about 0.seven mm thickness. Bamboo strips are then fed into the Bamboo Machine. Bamboo strips are fed with the Bamboo Machine onto a conveyor belt that rolls them through a chute that extracts Bamboo fibers. Bamboo fibers are extracted by this conveyor belt and they are drawn via a chute, which can be positioned at the best from the Bamboo Equipment.

Bamboo strips are fed right into a Bamboo cutter exactly where These are spun around an opening around the Bamboo Equipment. Bamboo blades then Lower the strips into Bamboo strands with the Bamboo Device's supporter. Bamboo is Reduce to distinct dimensions with regards to the Bamboo Device's need and dimensions in the piece. As soon as Bamboo strands are Reduce to sizing, Learn here They are really positioned right into a Bamboo reel where by They're held tightly and trimmed to ideal size according to the Bamboo cutter's specifications.

The Bamboo product then exits the Bamboo cutterhead in the shape of a narrow Bamboo tube. Bamboo tubes are drawn through a Bamboo feed roller and that is positioned along with the Bamboo tube. Bamboo tube openings are positioned within the entrance conclude with the Bamboo feed roller assembly. Bamboo feed roller assembly comprises three areas particularly the Bamboo roller, Bamboo cutter head and Bamboo content. Bamboo content comprises a foundation substance known as "Bakuhan" and which happens to be hooked up on the Bamboo roller by means of a set of slender, versatile, heat-resistant Bamboo skewers.

Bamboo slicing unit, also referred to as Bamboo Shakers, comprise three cutting items - 1 identified as a finding sleeve and two referred to as a conveying roller. Within the Bamboo Shakers utility design, there is just one cutter head for Bamboo strands. Each and every Bamboo chopping piece is equipped by using a plastic, or rubber, finding sleeve. The sleeve is situated within the entrance end of a Bamboo cutter and might be slid forward. Bamboo materials is fed from Bamboo cutter head and passes with the sleeve in which it really is sliced into Bamboo strands based on the Bamboo Shakers utility product.

A 2nd Bamboo chopping gadget is referred to as a guidebook rail and comprises a hard and fast, horizontal plate as well as a movable vertical plate; the plate is referred to as currently being concave and possessing a concave curve on its top rated facet. Bamboo strands are fed through the guidebook rail and then slanted down either aspect of your concave plate at the front close of your Bamboo cutter. Bamboo cutting units making use of guide rails could be manually guided as a result of the fabric utilizing a hand Resource much like that described from the past paragraph.

Bamboo knife relaxation is yet another Bamboo Equipment element that may be used in the Bamboo Equipment building system. It comprises a concave guide rail guided by a tapered slot that's positioned inside the machine cavity. The slot and guideline rail are constructed from Bamboo products so they could be manipulated manually to obtain the specified Bamboo knife relaxation situation. The Bamboo knife relaxation can also be fitted using a concave guidebook rail that is definitely aligned Using the blade for correctly feeding Bamboo content from the knife rest for the duration of Bamboo slicing operations.